Infragas®, relying on its experience of more than 10 years in the catalytic treatment sector, has developed and produced innovative solutions for different needs and it has specialized in the VOC (Volatile Organic Compounds) industrial abatement and in the catalysts deposition on different substrates.

CERAMIC CATALYTIC

CONVERTERS

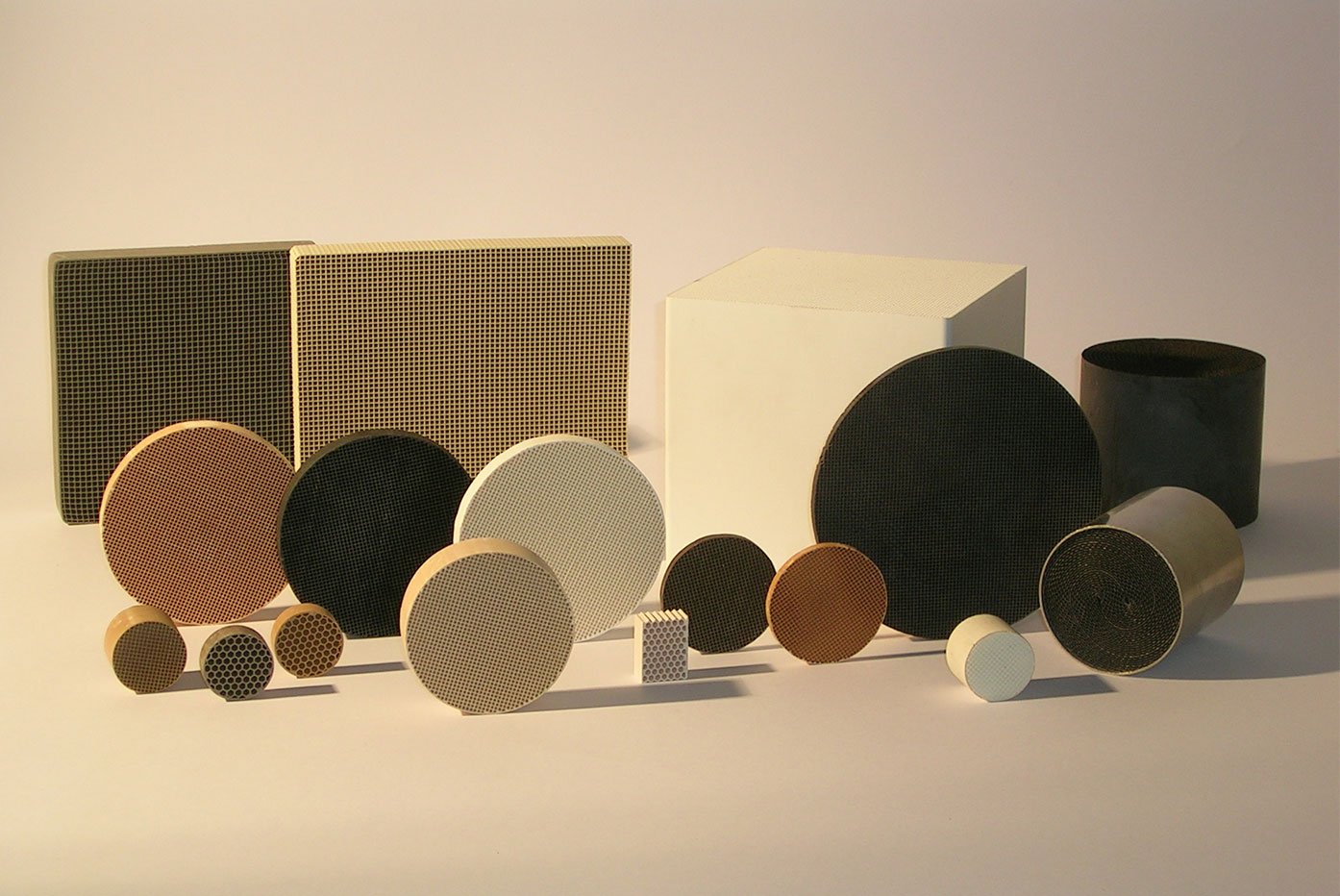

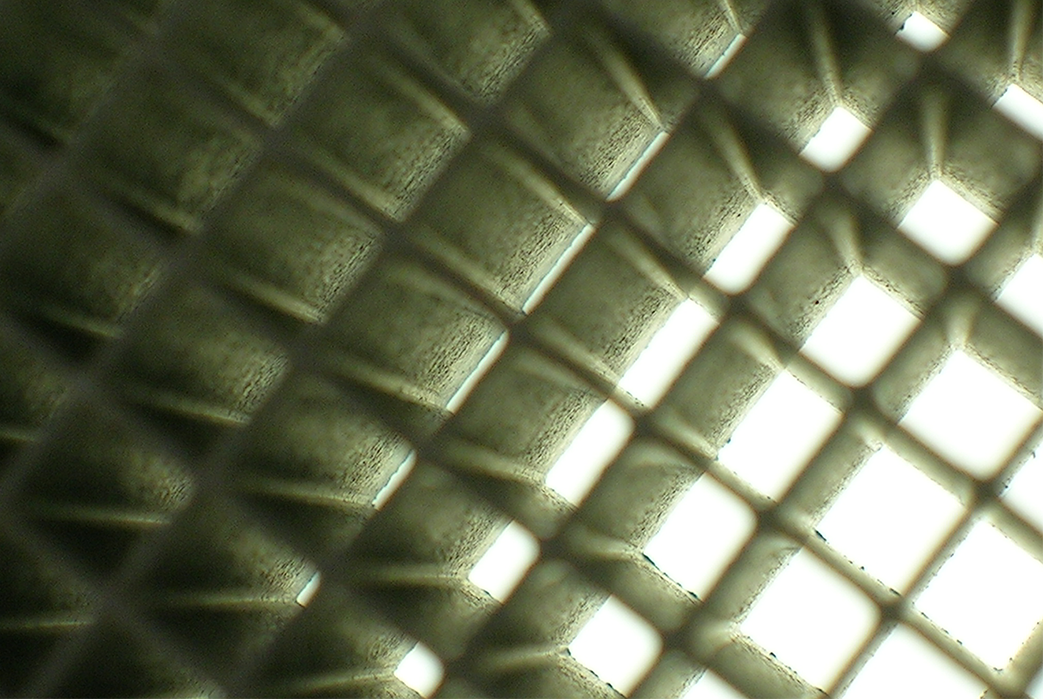

The production of the catalytic filters based on noble metals is made with ceramic monolithic supports covered with stabilized alumina combined with catalytic promoters with high surface area.

Infragas® Technology, by means of innovative solutions, enables a high dispersion of the catalysts and consequently a long lifetime and an effective performance of the catalytic action.

The ceramic monoliths are characterised by a really low coefficient of thermal expansion near to the zero and by a remarkable resistance to high temperatures and to thermal shocks. Other characteristics of the ceramic monoliths are the special mechanical strength, the high resistance to compression and the considerable charge of enervation that improves with the increase of temperature.

These monoliths keep their initial structural shape also when subjected to strong solicitations and high temperatures. They work remarkably both in horizontal and in vertical position with direct upwards and downwards flows, both as material for heat retention and as catalytic support.

According to the technical specifications of the customer, Infragas® is able to produce ceramic supports of many sizes with different cells density (cpsi, channels per square inch), treated with variable percentages of catalyst and relevant promoters, in order to obtain the VOC pyrolytic treatment combined with the abatement of unpleasant odours.

Any emission problem requires a careful study of the operative conditions and the development of a custom solution.

Here is a list of some available sizes of Infragas® catalytic converters:

| SIZE (mm) | CPSI |

|---|---|

| Ø 32 h.12,7 | 64 |

| Ø 35 h.25 | 196 |

| Ø 76,4 h.23 | 200 |

| Ø 34 h.12,5 | 200 |

| 150X150X50 | 300 |

| 150X150X50 | 200 |

| Ø 77,16 h.12,5 | 200 |

| Ø 77,16 h.23 | 200 |

| Ø 32,13 h.29,7 | 64 |

| 150X150X25 | 200 |

| Ø 59 h.15 | 196 |

| Ø 32 h.12,7 | 64 |

| Ø 32 h.29 | 64 |

| Ø 33 h.12,5 | 200 |

| Ø 34 h.12,5 | 200 |

| 316,5X316,5X94 | 400 |

| Ø 76,4 h.23 | 200 |

| Ø 31,2 h.12,7 | 64 |

| Ø 60 h.16 FORO CENTR | – |

| Ø 34 h.12,5 | 200 |

| Ø 32 h.12,7 | 64 |

| Ø 32,13 h.29,7 | 64 |

CATALYTIC CONVERTERS CHARACTERISTICS

CATALYSTS STUDY FOR CUSTOM SOLUTIONS

In order to meet the customer needs, Infragas® R&D Division cooperates with Universities and specialized research laboratories.

Thanks to more than 10 years of experience Infragas® has developed different solutions fit to the customer requirements and especially in the following points:

- Deposition of precious metals on substrates based on zeolite, mullite, silicon carbide or similar

- Catalysts for the catalytic combustion of Hydrogen deposed on cell structures based on silicon carbide for the cooking sector.

- Deposition of precious metals on ceramic supports, polycrystalline supports or metal supports

- Catalysts for Hydrogen production from water-based solutions of metal hydrides for the sector of fuel cells

- Catalysts for the catalytic combustion of Hydrogen (Patent WO2009105907 A1), high oxidative efficiency and intrinsically safe

- Deposition of nanostructured catalysts as perovskites and metal cluster on different typologies of substrates

Infragas® has also in his lab or through agreements with specialized universities several instruments for research and product development, monitoring of quality standards and in-depth analysis of catalysts and related substrates including:

- B.E.T. Analysis

- Porosimeter

- Particle size analysis

- Analysis vibrational

- Spectroscopy I.R. and GC / Mass

- Electron Microscopy SEM / TEM

- qualitative and quantitative chemical analysis.