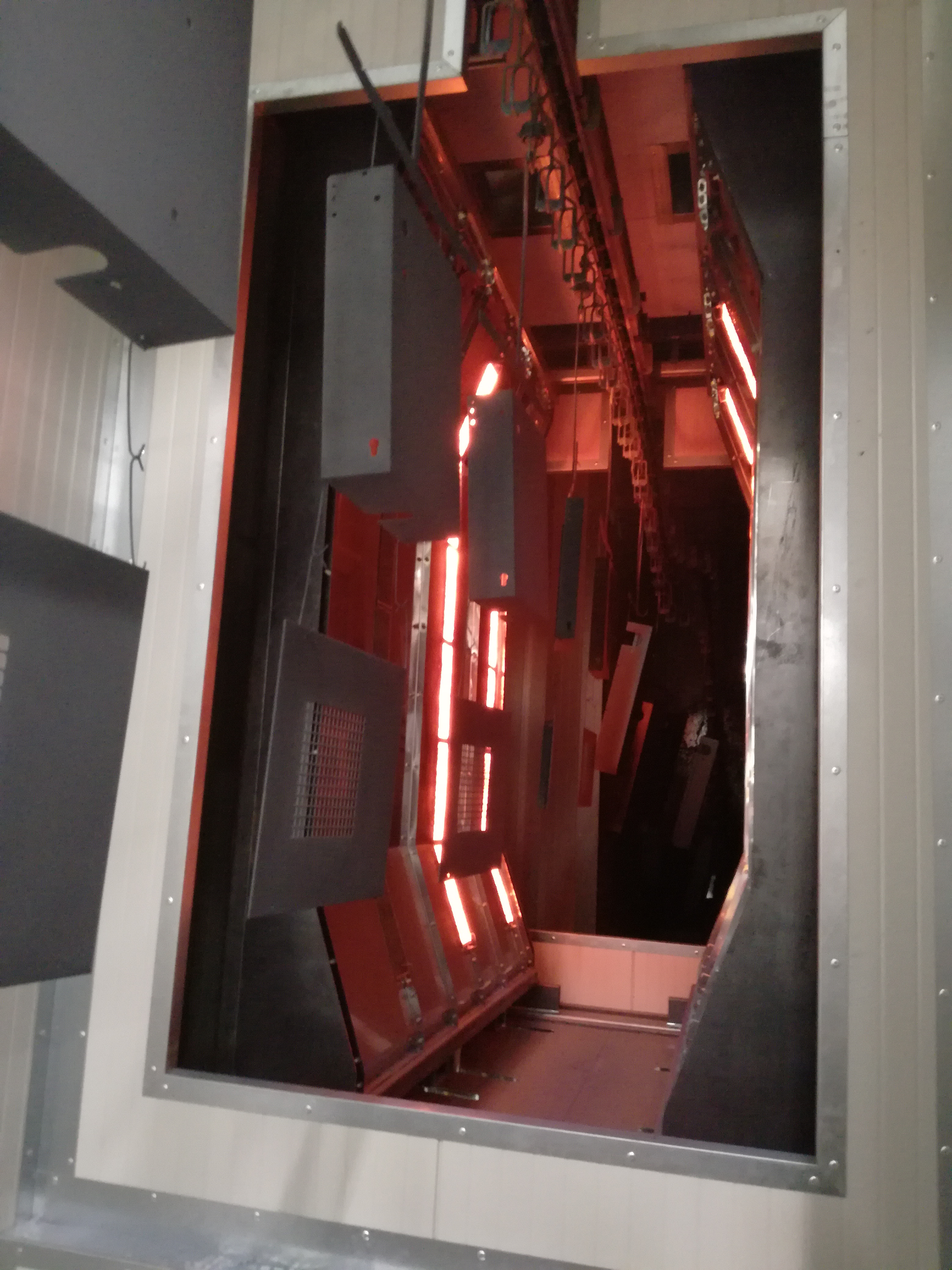

PRODUCTIVITY INCREASE THANKS TO THE INTEGRATION OF AN INFRARED GAS OVEN: THE “RHT” POWER

The installation of the Infragas® RHTs before a traditional hot air oven is the solution to melt the powder in only 3 minutes on the most different parts with complex shapes, from train seats to construction bars. The infrared radiation lets reaching 170°C on the powder and the following traditional oven completes the powder polymerization. Coating contractors demand highly flexible systems and equipment in order to meet their diverse production requirements, arising from the need to quickly coat components with different material and sizes. Another challenge they often face is the reduced space available for machinery in their factories. The solution is the installation of the infrared high temperature RHT Infragas®, infrared energy in short wavelengths, with immediate start-up, adjustable power up to the 50%.

For further info, we invite you to read the article https://www.ipcm.it/en/riviste-ipcm/2020/62/open/170-172/