WORLDWIDE GLOBAL ASSISTANCE

PROJECTS

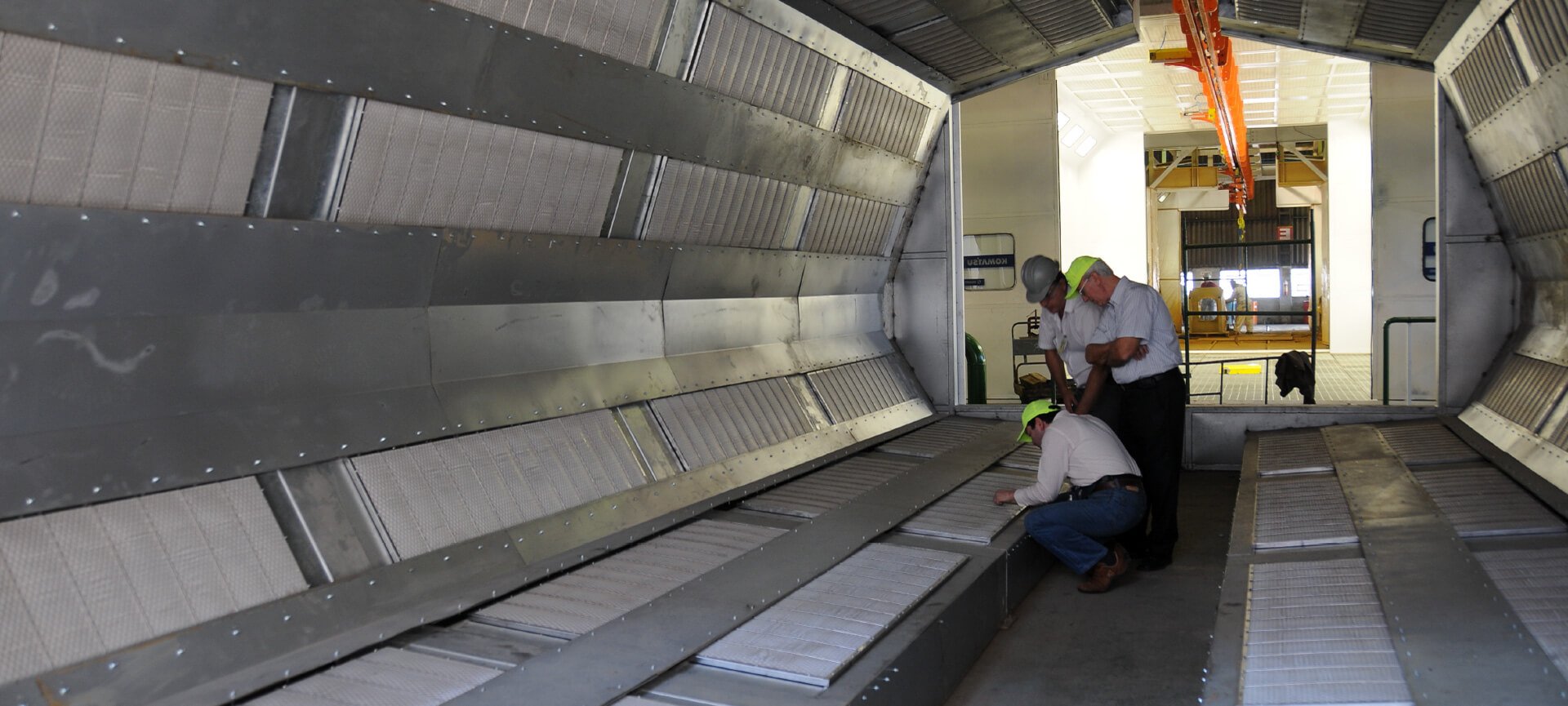

We develop, in cooperation with our customers, complete projects that include gas connections and electrical controls (gas trains, electronic control boards and all necessary components).

TAILOR-MADE SOLUTIONS

Infragas® Research Department enables us to develop performing and innovative solutions: compact systems equipped with CUSTOM-ENGINEERED infrared gas emitters.

ASSISTANCE

Our commitment is to give constant availability and technical support so that the customer can always rely on a high performing thermal process.

Why Infragas®

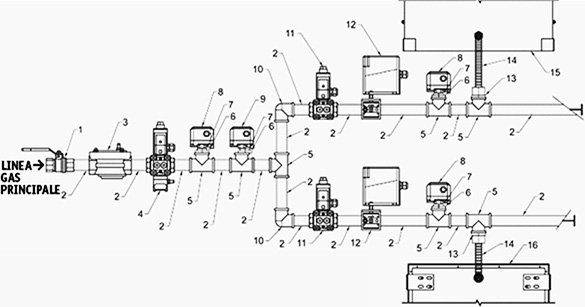

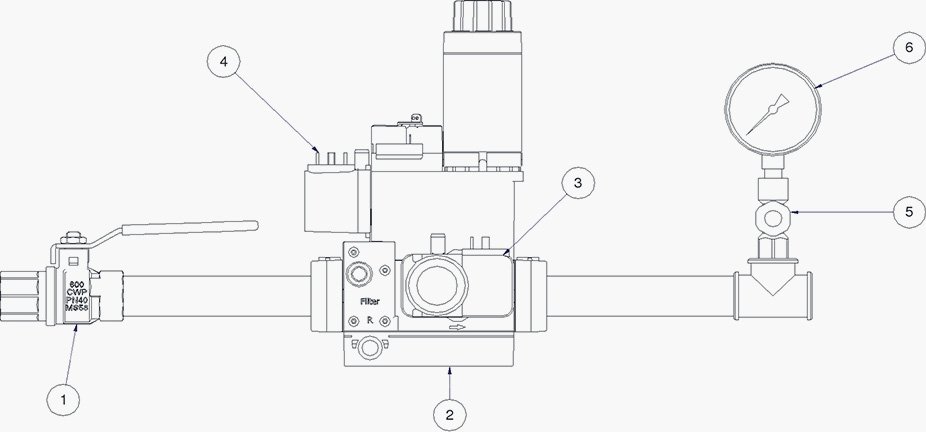

Gas Train Scheme

Infragas® supports the oven manufacturer with complete solutions that include dedicated components as max-min gas trains or modulating gas trains to optimize the system control and reduce energy consumption.

POS description

1. Ball valve

2. Pipe

3. Gas filter

4. Safety solenoid valve

5. Tee

6. Reducer bushing

7. Union

8. Pressure switch for min flow

9. Pressure switch for max flow

10. Elblow 90°

11. Solenoid valve

12. Modulating valve

13. Reducer bushing

14. 1/2” Flexible gas line

15. BoosterCat®

16. InfraCat®